CUBIC project aims at developing innovative biobased materials from which intermediate semi-finished B2B products are manufactured in an intermediate processing stage. This production concept can help companies streamline production processes, save time, and accelerate time-to-market. The combination, thanks to applying circular-by-design principles allows an efficient integration (automotive seat demonstrator) and assembly (type IV H2 gas vessel) of final complex end-products with comparable functional properties and with a circular end-of-life approach.

Diversified bio-based materials, and their applications.

The plastics manufacturing sector is at the main point of a variety of value chains. The potential scale production of CUBIC concept and the developed manufacturing processes goes far beyond the selected value chains. It is based on modularity: production of intermediate formats which are used as components of the final or finished products.

Using B2B standard semi-finished formats allows a high scale of flexibility products for a plethora of applications and sectors and permits to have shot-chained production models and contain overall product prices, thus facilitating replication in more applications.

Owing to increasing environmental concerns, this concept is gaining momentum and CUBIC aims to be the first of its kind to introduce and promote circular biobased composites with such a model. The project also aims to demonstrate that, at least for the selected value chains, the selected B2B intermediates can be as competitive as petroleum-based counterparts following this modularity approach and proper eco-design. It allows to carry out the experimental and digital modifications, obtaining physical products for tradeshow, also opening two direct penetration markets.

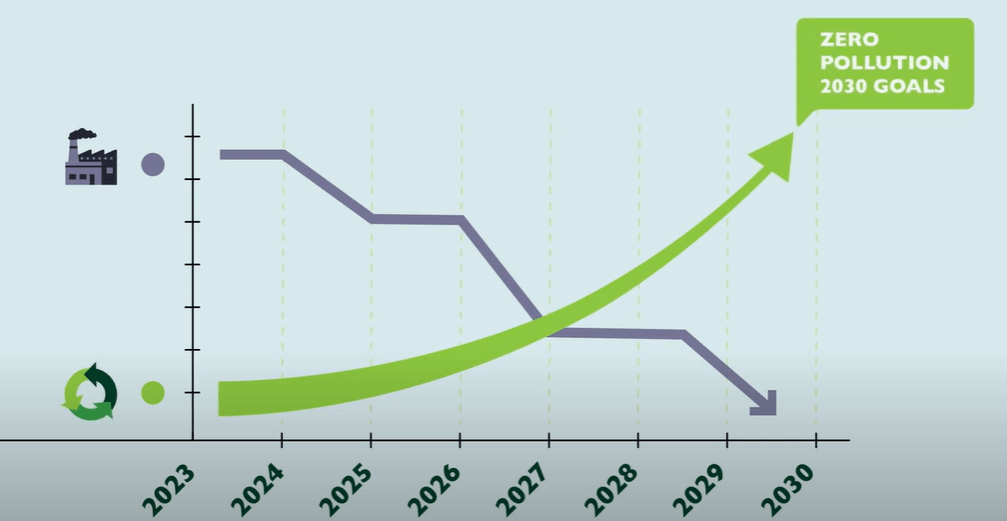

Contribution to increasing the availability of renewable carbon-based complex structures, their circularity, and addressing zero pollution goals.

CUBIC project contributes to increase the availability of renewable carbon sources in order to shift towards more sustainable and climate-friendly production and consumption (especially for the chemistry and plastic sector).

Apart from renewable carbon and circularity goals, CUBIC project also addresses zero pollution 2030 goals in terms of contributing to reduce soil and water contamination related to waste generation and potential microplastic levels considered harmful to human health or natural ecosystems. In particular, the recyclability of thermoset gas vessels (due to design principles, novel materials, and re-shaping methodologies) will imply avoiding the current landfilling practices concerning composite materials.

Develop innovative production systems in the biobased industry.

CUBIC project will contribute towards an innovative circular and sustainable production system for the European manufacturing sector. This systemic model is built on three basic pillars:

1. Agility by means of manufacturing pre-fabricated or modular parts which is the core of CUBIC concept based on production of complex products by using B2B intermediate or semi-finished ones. Intermediates permit manufacturing technologies boost for end-products, based on smart conformal technologies, (see INNOVATION 3)

2. Decentralized manufacturing to produce flexibly, and faster, using local resources (regional biobased materials & feedstocks, local labour workforce) permitting more interaction and co-creation with final customers.

3. Manufacturing-as-a-Service which will be characterised by highly customised, more accessible biomaterials to manufacturers & consumers, that succeed in decreased production costs & time. This manufacturing concept is possible thanks to the digital twin process.

Develop innovative biobased products.

Modular semi-finished intermediates make the conception of breakthrough bio-based end-products possible, through the application of innovative smart and more sustainable technologies. CUBIC end-products could be applied to a wide array of market sectors, that are 100% circular.

The two (2) innovative demonstration cases have been selected for their validation due to their importance in contributing towards a more circular economy as defined in the Circular Economy Action Plan (CEAP). With the view to push plastic recyclability, the 2 innovative cases are considered disruptive applications focused on energy storage and sustainable transport part oriented to efficient and recyclable mobility, with large potential in the electric vehicle.

Incorporate environmental sustainability & circularity in biobased systems.

CUBIC project will act as an example to introduce circular practices and new approaches that will be needed in European future factories to motivate a change from a mass production model to a mass customisation, which relies on decentralised, cleaner, and greener, more flexible, and smaller factories in which the modularity concept (production and trade of B2B intermediates) is supported by the uptake of disruptive technologies and digital transition.

In conclusion, shifting to a circular way of producing and consuming, requires: i) fundamental changes in the way products and services are conceived; ii) new types of human-driven innovations and relationships that include policymakers and consumers, iii) agile interaction and communication between producers, retailers, consumers, and service providers, iv) adding alternative notions of material and product value and associated revenue models.

Read here the innovation of CUBIC project in article 1, article 2 and article 3.

Click here to see project’s video.