The first step of CUBIC’s innovation is to develop three (3), 100% biobased materials as building blocks to produce B2B intermediate formats.

- biobased endured 3R-CAN epoxy system

- biobased polyamide grades (bioPA)

- biobased lignin derived carbon fibre (bioCF)

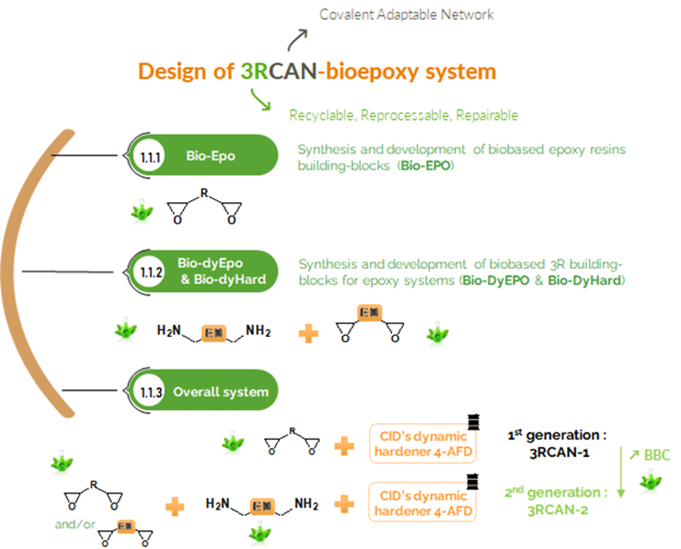

1. Advances on 3R-CAN-bioepoxy system (thermoset resins).

An epoxy system is composed by 2 main components: the epoxy resin & a co-reactant called hardener. Most research focused on the development of biobased epoxies, only concentrates on the substitution of the resin itself. However, the challenge remains in finding adequate biobased substitutes for both epoxy resins and hardeners.

CUBIC partner, Specific Polymers (SP) is working on the valorisation of sustainable biobased phenols, to propose biobased epoxy resins that can substitute currently used Bisphenol-A (BPA) based resins.

SP is also working on the synthesis and application of a biobased alternative to 4-AFD hardener. The combination of both will allow CUBIC project to start with a biobased epoxy system of at least 80% biobased content and increase it until reaching 100%.

Covalent Adaptable Networks – CAN are chemical moieties that can undergo modifications in their inner structure based on efficient associative and dissociative exchange mechanisms that enable topology reconfiguration without loss of network integrity by thermal activated bond-exchange processes.

These can be incorporated either in the structure of the resin or the hardener or both. CUBIC partner, CIDETEC has developed an innovative and ground-breaking based epoxy resin CAN system, by using a dynamic and reversible cross-linking system based on a diamine hardener containing a reversible aromatic disulfide bond in substitution to traditional diamines.

The use of this resin in the manufacture of composite materials allows the development of reprocessable, recyclable and repairable (3R) thermoset composite materials. Within CUBIC project 80 to 100% biobased alternative to current dynamic hardener, will be researched and incorporated to complement the 3R system and increase the overall biobased content value up to 100%.

2. Advances on biobased Polyamides building blocks and customised novel polymer grades (thermoplastic resin).

Polyamide (PA) is one of the most utilized industrial engineering plastics due to their excellent properties, such as high impact and tensile strength, electrical insulation, heat and abrasion resistance, elasticity, biocompatibility and the ability to adapt these properties to specific applications.

CUBIC project is proposing a new concept of high-tech biobased PA thermoplastic composite for engineering applications.To do this, project’s partner Novamont, will use vegetable oil feedstocks and used cooking oils to obtain biobased building blocks to produce bio-PA with properties suitable for the target applications.

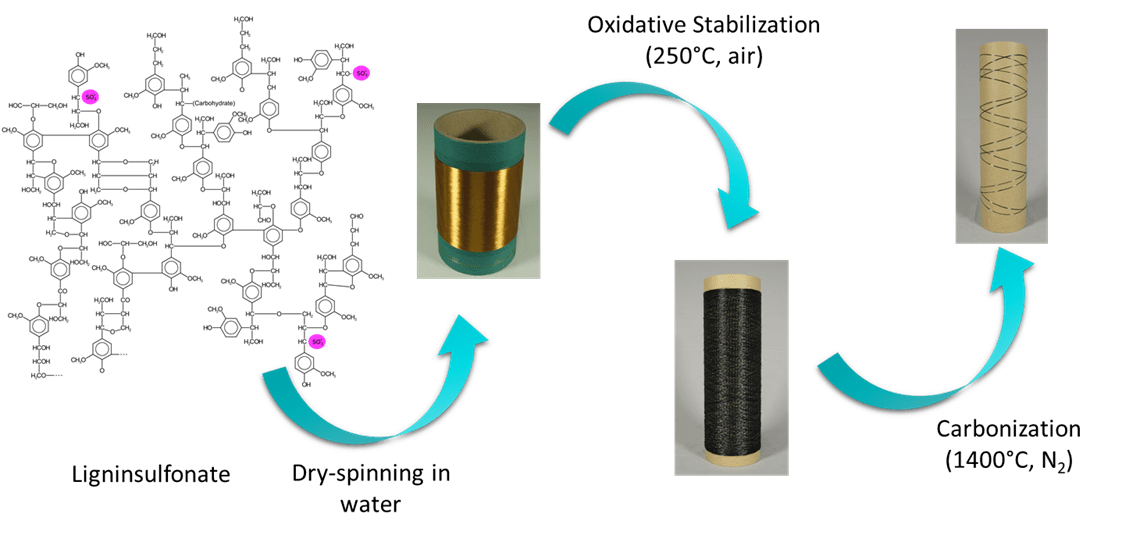

3. Advance on natural fibers from lignin sources – high mechanical grades of biobased carbon fiber (CF).

Polyacrylonitrile (PAN) is a versatile polymer widely used as precursor for the fabrication of carbon fibres (95%).

CUBIC is developing two promising pathways for lignin-based carbon fibers: Lignin/TPU precursors, which are processable by melt-spinning with broadly available extrusion technology, and dry-spun Lignin-salt/PVP precursors, which prevent using toxic solvents like in wet-spinning of comparable Lignin-Precursors like blends with Cellulose. CUBIC will be the first scaled production of lignin-based CF weaves, thanks to partner DITF’s, proprietary oven technology and patented knowledge.

In conclusion, the general objective of CUBIC project is to improve the sustainability and circularity of complex products. They will be made of high-tech advanced multi-material composite thermoset and thermoplastic structures, by developing novel circular biobased alternative materials. Click here to learn more about the project’s objectives. Also, you can watch CUBIC’s video on its YouTube channel.